Ageneau Group Chooses Generix WMS to Boost Growth

Puteaux, France, January 21, 2025 – Generix, a global business software company offering an expansive portfolio of SaaS solutions for…

Bona: Building Operational Excellence with Solochain WMS Read the use case

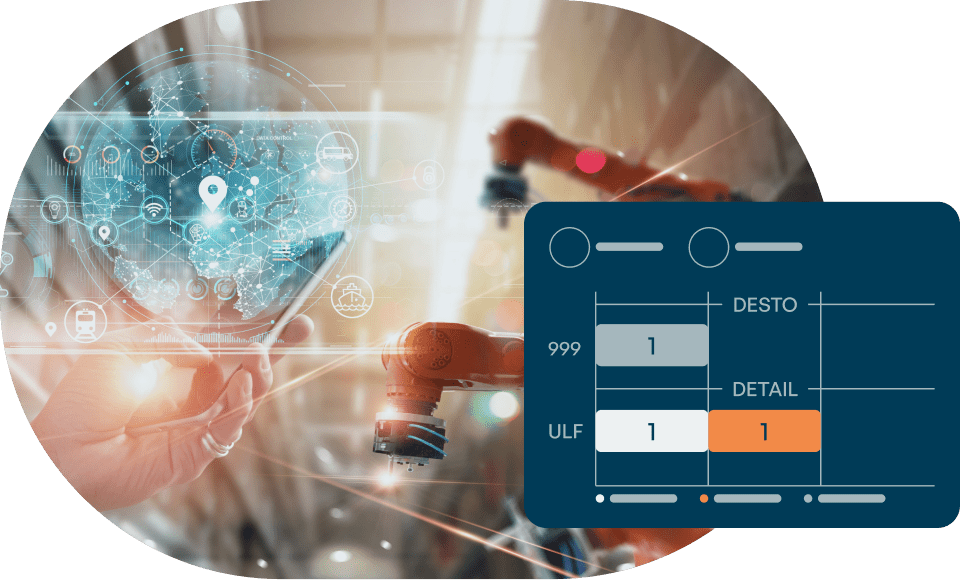

Intelligently optimize all warehouse resources

Generix Resource Management System (RMS) is a new AI-powered SaaS application providing intelligent forecasting, planning, and analytics into a single environment – so you can optimally utilize all your warehouse resources

CONSISTENCY

PERFORMANCE

FLEXIBILITY

Intelligently manage and optimize every job, every task,

every resource in every warehouse.

Use embedded AI to intelligently forecast & plan across all your WMS & HR data – so you can assess any constraint, predict workloads, and plan effectively via a single experience.

Work across locations and integrate with any WMS with RMS APIs – so you can manage all your resources, from people to equipment and machinery, and maximize productivity, utilization, and employee engagement.

Get instant results to adjust the utilization of your resources within lead-time constraints and as events happen with RMS built-in analytics – so you can continuously rethink your warehousing processes as needed.

Integrations

Generix makes scaling your supply chains easier. Seamlessly integrate your current systems and applications with Generix’s 17+ supply chain software solutions to grow your operations as fast, and as far, as you need.

Optimize and organize your yard operations

Data-driven insights for supply chain efficiency

Centralize communications with your carriers

Accelerate your client’s deployment and fulfillment activities

Track live shipments and provide accurate ETAs

Unlock operational efficiency across your physical and critical workflows. Benefit from our best-of-breed SaaS solutions and expertise, backed by high-performance partners and seamless implementation and advisory support for your business journey.

Puteaux, France, January 21, 2025 – Generix, a global business software company offering an expansive portfolio of SaaS solutions for…

To optimize inventory management, retailers and suppliers are increasingly turning to Vendor Managed Inventory (VMI) tools that transfer the responsibility…

Generix is proud to once again be recognized in Gartner 2025 Magic Quadrant™ for Warehouse Management Systems (WMS)

Frequently asked questions

Labor management ensures an efficient flow of products, services, and information while minimizing costs. It involves coordinating supply chain processes and optimizing logistics. Generix’s Resource Management System (RMS) improves warehouse labor management. It uses AI to analyze performance, predict lead times, and optimize resource allocation.

The RMS coordinates logistics activities, reduces costs, and enhances customer satisfaction. It is essential for optimizing logistics processes and achieving better performance. For more information, refer to the dedicated article on this warehouse resource optimization solution.

A labor management system is a specialized software designed to optimize workforce productivity and efficiency. It assists in planning, monitoring, and managing employees’ work within an organization. Generix’s labor management system software provides tools for scheduling, time and attendance tracking, performance analysis, and workforce forecasting, aiding in effective labor management and enhanced operational efficiency.

A labor management system improves productivity by providing real-time insights into workforce performance, identifying areas for improvement, and enabling better resource allocation. It helps in optimizing staff scheduling, reducing labor costs, and ensuring compliance with labor regulations. Generix’s software enhances decision-making with accurate data, leading to a more efficient and productive workforce.

Yes, Generix’s labor management system can integrate seamlessly with other HR systems. This integration allows for a unified approach to managing employee data, payroll, benefits, and other HR processes, ensuring consistency and efficiency across different HR functions.

Absolutely. Generix’s labor management system is designed to be flexible and customizable, catering to the unique needs and requirements of different industries. Whether for retail, manufacturing, logistics, or other sectors, the system can be tailored to meet specific operational demands and workforce management challenges.

Key features of Generix’s labor management software include employee scheduling, time and attendance tracking, performance management, labor cost analysis, and compliance management. These features are integrated into a user-friendly platform, providing managers with the tools necessary for effective workforce management and strategic planning.

Labor management software supports employee engagement by promoting transparency in scheduling and performance metrics, fostering a fair and communicative work environment. It allows employees to access their schedules, submit requests, and receive feedback on their performance. This involvement and clarity in workplace processes enhance employee satisfaction and engagement, which in turn contributes to higher productivity and morale within the organization.

Reach out to learn more about labor tracking and employee management software solution for growing teams.