Connect your business network with next-gen collaboration technology

Do you want to deeply modernize your collaboration technology without disruption? To help connect businesses together, we are pleased to…

Bona: Building Operational Excellence with Solochain WMS Read the use case

Follow every order from dock to doorstep

Discover the efficiency of Generix’s order tracking software. It provides shippers with detailed visibility into the status of their domestic and international orders as they travel from suppliers to factories to warehouse locations.

Real-time order traceability gathers dynamic, up-to-the-minute order insights throughout the entire order lifecycle, enabling shippers to identify bottlenecks, optimize routes— all while keeping customers in the loop.

Get a real-time view of all your orders and their statuses across transport, factories, warehouses, and subcontractors’ operations.

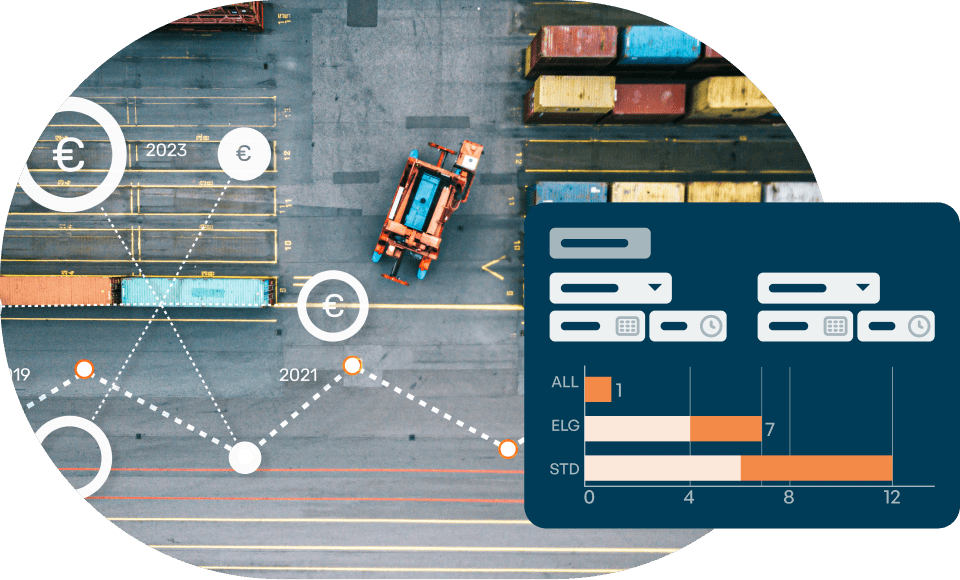

Charts, graphs, and dashboards offer a clear visual representation of how well the actual execution aligns with planned timelines, expected milestones, and projected performance metrics.

Gather traceability data from all partner systems thanks to Generix’s extensive list of pre-built connectors, APIs, and traditional interfaces.

Set custom parameters to detect order anomalies like delays, inventory shortages, or unexpected changes in order status.

Share insights, live order updates, and associated documents with third-party providers and suppliers without leaving the platform.

Do you want to deeply modernize your collaboration technology without disruption? To help connect businesses together, we are pleased to…

While lesser known than accounts payable automation software, accounts receivable automation solutions automate the capture, validation and process of invoices…

Have you ever gone into a store and discovered the product you wanted is out of stock? Or, have you…

Drive operational efficiency across warehouse activities

Build a lean, demand-driven supply chain

Optimize and organize your yard operations

Collaborate with third-party logistics providers

Data-driven insights for supply chain efficiency

Unlock operational efficiency across your physical and critical workflows. Benefit from our best-of-breed SaaS solutions and expertise, backed by high-performance partners and seamless implementation and advisory support for your business journey.

Our order tracking software provides comprehensive features including real-time tracking, automated updates, and integration with existing order management systems. It’s designed to enhance efficiency and accuracy in order management, ensuring a smooth experience for both businesses and their customers.

Our order management software streamlines operations by automating key tasks, providing detailed analytics, and facilitating easier communication between departments. It effectively reduces errors and increases the speed of order processing, making it ideal for any B2B sales order management software needs.

Yes, our order tracking system is designed for seamless integration with various platforms, including other OMS software and ERP systems. This integration capability ensures a unified approach to order management, enhancing data accuracy and process efficiency across your business operations.

Absolutely. Our order management platform is scalable and robust, making it ideal for businesses of all sizes, including those with large-scale, complex operations. It supports a wide range of functions from order entry to fulfillment, ensuring efficiency at every stage.

Our B2B order management software is tailored to meet the unique demands of B2B transactions. It offers features like bulk order processing, complex pricing structures, and customer-specific catalogs, all designed to streamline the B2B sales process.

Our order fulfillment software stands out for its real-time tracking capabilities, intuitive interface, and advanced analytics. It not only streamlines the fulfillment process but also provides valuable insights to continuously improve your order management strategy.

Work with our team to build your ideal supply chain software stack and tailor it to your unique business needs.