How Vendor Managed Inventory (VMI) Strengthens Supply Chain Resilience and Collaboration

To optimize inventory management, retailers and suppliers are increasingly turning to Vendor Managed Inventory (VMI) tools that transfer the responsibility…

Bona: Building Operational Excellence with Solochain WMS Read the use case

A WMS is a big-picture investment that should be backed by a long-term strategy. Which warehousing pain points does the company seek to address with a new WMS? Will it integrate seamlessly with existing and future technology solutions as well as their enterprise resource planning (ERP) system? Does it offer functionality tailored to manufacturing?

The right WMS can improve the movement of goods and parts, improve tracking and reporting, provide improved speed and efficiency, among other benefits. Here are 5 key considerations for manufacturing companies looking to select and integrate a new WMS.

When considering a WMS replacement, ease-of-use for employees is key. A WMS shouldn’t make simple tasks more complex or add excessive training time to managers’ busy schedules.

This doesn’t mean workers will instantly adopt a new WMS. Rome wasn’t built in a day and the same should be true of your WMS integration.

Look for ease-of-use when navigating menus, help screens, as well as data entry, retrieval and the creation of reports and charts. The WMS should contain built-in self-help tools, that are easy to access and understand, to reduce training time and troubleshooting. This will reduce margin for error as employees are enabled to use business tools correctly and efficiently.

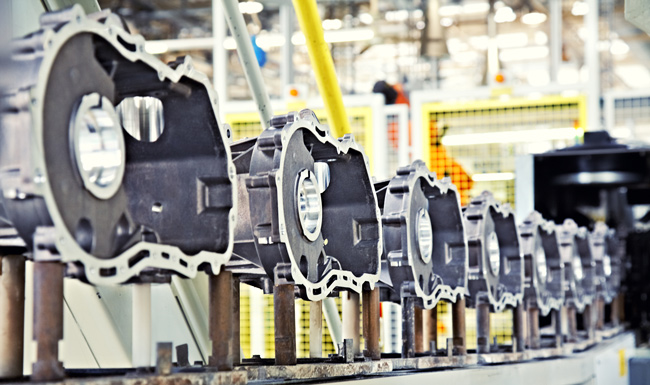

Manufacturing companies rely on their WMS for efficiency, consistency, and quality control by improving the speed in which goods are processed and shipped. Investing in the right WMS can decrease excess inventory, improve order fulfillment, and reduce the cycle time of orders.

When selecting a WMS consider how it empowers employees with more visibility, control, and fast and efficient key data access.

Employees should be empowered to better manage the flow of inventory, track items in real time, predict inventory fluctuations, and keep a close eye on items being shipped.

A WMS is seldom a one-size fits all solution. For this reason, ensure the system you select has the features and functionality needed to meet industry-specific requirements.

Manufacturers should identify the unique aspects of their company that make them truly niche. Does the business have a higher than usual amount of product they are attempting to produce and deliver to clients with a specific timeframe? Do they require coordination between multiple warehouses? Is the WMS built with technology that can handle high-volume transaction processing?

Make sure the WMS provider can provide relevant use cases for manufacturing pertaining to businesses of similar size and scope.

One of the first things to consider when upgrading your WMS is the ease in which it integrates with an existing ERP. For companies also seeking to overhaul their ERP, it is wise to upgrade both in tandem to ensure they are selecting the correct solutions for years to come. When choosing a WMS, ensure they have compatibility with leading ERP providers like:

Choosing a system that meets requirements today but also for years to come can be daunting. This is where manufacturing companies must ensure a clear technology roadmap so they can choose a WMS that grows and scales with their business.

In general, a WMS should be compatible with industry leading ERPs and hardware brands, different business models and sizes, and built on an open platform that is compatible with other SaaS products and integrations.

This will ensure flexibility and scalability for years to come.

Though there may be resistance within an organization to move on from a familiar legacy WMS, it’s critical to understand the potential costs of hanging on to an outdated one.

Older systems can quickly become unreliable, non-secure, or obsolete. They have likely undergone custom in-house development, which can lead to systems becoming too costly and time consuming to maintain, and nearly impossible to integrate with newer systems or technologies.

It’s key for manufacturing companies to consider today’s customer, but also who they will be serving for years to come.

Innovative technologies like Edge computing, IoT devices, and 5G are fast becoming table stakes for warehousing and supply chains and will continue to evolve.

Investing in the latest WMS technology today can ensure years of reliability and improved efficiency.

Analog Devices (ADI) provides signal processing equipment to over 100,000 customers worldwide. Before switching to a WMS solution, warehouse employees manually tracked inventory and parts through an excel spreadsheet. This led to confusion throughout the warehouse about the location, condition, and version of each spare part.

Integrating a Generix Groups SOLOCHAIN WMS enabled employees to track and locate their inventory with increased efficiency as well as giving them the flexibility to optimize and consolidate their picking methods.

Learn more about SOLOCHAIN WMS

Generix Group provides a series of solutions within our Supply Chain Hub product suite to create efficiencies across an entire supply chain. Our solutions are in use around the world and our experience is second-to-none. We invite you to contact us to learn more.

To optimize inventory management, retailers and suppliers are increasingly turning to Vendor Managed Inventory (VMI) tools that transfer the responsibility…

In an ever-evolving logistics environment, agile and precise warehouse resource management is essential to remain competitive. With increasing volumes driven…

France’s electronic invoicing reform relies on a Y-architecture, where Partner Dematerialization Providers (PDPs) play a central role in issuing and…

Work with our team to build your ideal supply chain software stack and tailor it to your unique business needs.