How Vendor Managed Inventory (VMI) Strengthens Supply Chain Resilience and Collaboration

To optimize inventory management, retailers and suppliers are increasingly turning to Vendor Managed Inventory (VMI) tools that transfer the responsibility…

Bona: Building Operational Excellence with Solochain WMS Read the use case

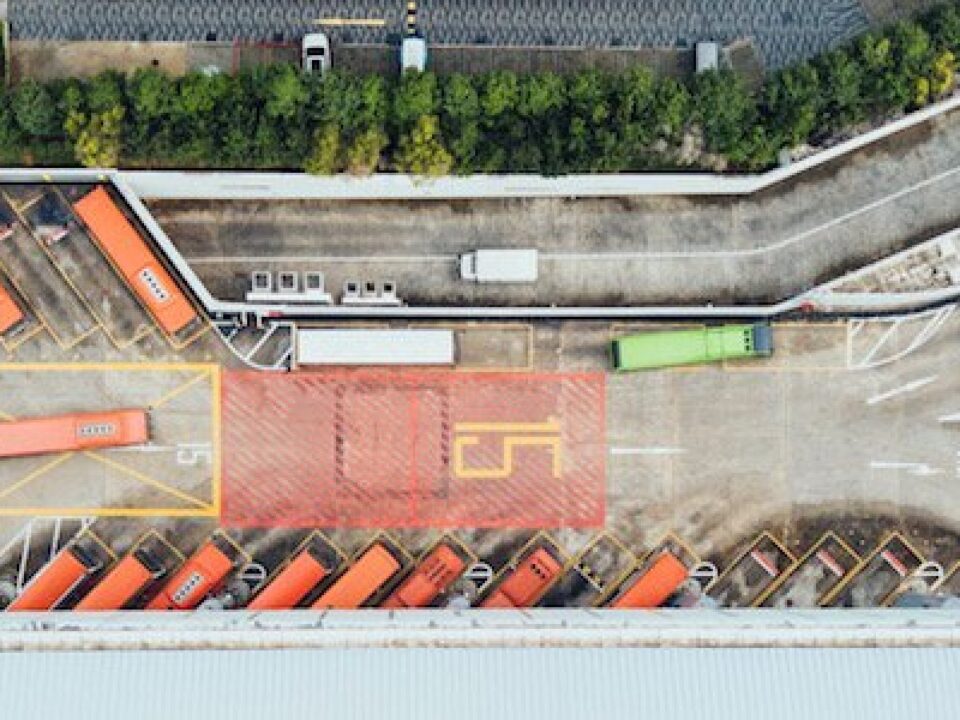

The improvement of your transportation performance relies on 3 main factors:

Although cost reduction is a prime goal, the cuts should not negatively impact delivery times. Companies should thus aim to optimize transportation by using these 4 operational levers:

TMS solutions integrate management tools capable of determining the optimal truck load in real time as well as the best delivery routes to cut significant costs. However, to satisfy both customer and company needs, these solutions need to remain flexible. For that, think about planning and using different delivery strategies.

Read also: Reducing transportation costs: the main challenges to overcome

Studies recently carried out come to the same conclusion: within one year of implementing a TMS, companies increased their cost savings by 5 to 10%. Furthermore, a study conducted by Supply Chain Digest estimates annual cost savings on freight to be between 5 and 15%, with an overall reduction in transportation costs, including staffing and management costs, coming in at 10 to 30%.

In 2014, ARC-Advisory Group reported a reduction in transportation costs from between 5 and 10% according to more than 40% of respondents with 23% announcing savings over 10%. Since, the percentage of companies that saw reductions over 10% has increased, as revealed by the 2017 version of this study, with average cost savings remaining steady.

On the same topic: Optimization of transport costs: TMS in the front line

What’s interesting with a TMS implementation is that companies don’t just seek financial gains but also real time visibility on their shipments. Over the past year and a half, Gartner advisory firm has observed a growing interest among companies to implement a TMS that will allow them to control their transportation flows and inform their customers of delays.

To optimize inventory management, retailers and suppliers are increasingly turning to Vendor Managed Inventory (VMI) tools that transfer the responsibility…

In an ever-evolving logistics environment, agile and precise warehouse resource management is essential to remain competitive. With increasing volumes driven…

France’s electronic invoicing reform relies on a Y-architecture, where Partner Dematerialization Providers (PDPs) play a central role in issuing and…

Work with our team to build your ideal supply chain software stack and tailor it to your unique business needs.