Generix Launches Solochain Now – Packaged Solution to Deploy a Complete SaaS WMS in as Little as 16 weeks

Chicago, IL, March 17, 2025 – Today, at ProMat 2025, Generix, a global business software company offering an expansive portfolio…

Bona: Building Operational Excellence with Solochain WMS Read the use case

Turn each digital connection into digital value

Do you want to become the next leader of the networked economy? Generix can help you drive with confidence your most mission-critical digital business processes in supply chain, finance and commerce. And you can build a fully digitized business network to connect and collaborate with all your trading partners with the ultimate sophistication: simplicity.

News

Optimize Routes

1M+

transport operations per year

Streamline Communication

2B+

EDI messages processed per year

Increase Productivity

500M+

electronic invoices processed per year

Run your critical business operations and collaborate across your business network with state-of-the-art SaaS solutions built on modern technology and latest security standards. And make data work for you to get intelligent insight to best optimize all your resources.

Run a sustainable and profitable supply chain and expand collaboration at global scale

Drive reliable and automated invoicing across the end-to-end purchase-to-pay scenario.

Drive the entire consumer journey in retail with end-to-end commerce scenario (B2C).

Bring all trading partners in your business network and automate the exchange of electronic documents.

Build a resilient supply chain capable of managing your end-to-end operations, anticipating and adapting at market speed to changes happening in real-time, while minimizing the impact on the environment.

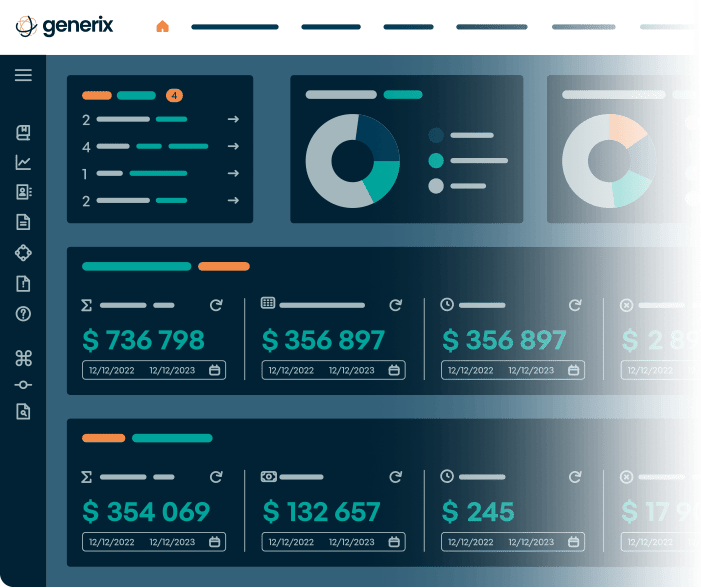

Recognized for flexibility and comprehensive functionality, see why 2,000+ warehouse leverage Generix and SOLOCHAIN WMS solutions.

Automate your data flows, financial transactions, invoicing and payment processes to reduce manual data entry errors and ensure regulatory compliance in 60+ countries.

Explore our complete portfolio of SaaS solutions and services in supply chain, finance, commerce, integration and collaboration.

Tell us about your business needs.

Chicago, IL, March 17, 2025 – Today, at ProMat 2025, Generix, a global business software company offering an expansive portfolio…

Generix —a global business software company offering an expansive portfolio of SaaS solutions for supply chain, finance, commerce, and B2B…

Generix is a software provider offering a portfolio of cloud-based solutions and services powered by AI to confidently manage the…